Membrane Bioreactor (MBR)

Membrane Bioreactor (MBR)

Membrane Bioreactors are used to process effluent, reducing chemical oxygen demand (COD) and suspended solids by means of micro-filtration. The resulting treated water will be of a high quality enough to be discharged to coastal, surface or brackish waterways or to be recycled or used for irrigation.

Other advantages of MBRs over conventional processes include small footprint, easy retrofit and upgrade of old wastewater treatment plants.

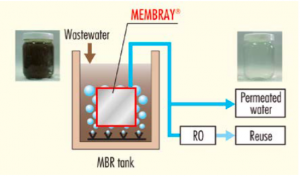

The Toray MBR are used in a submerged system, whereby the membranes are immersed in and integral to the biological reactor.

Why are they used?

The Toray MEMBRAY® submerged flat sheet membrane module, when used as a component of a membrane bioreactor (MBR) system, effectively removes suspended solids.

Using membranes to separate sludge ensures much higher quality for treated water free from suspended solids. The system may be used in combination with RO membranes producing water quality as good as potable water.

- Membranes can retain activated sludge at high concentrations, allowing BOD/COD as well as nitrogen to be removed more efficiently.

- The unique membrane configuration, having an immense number of minuscule pores delivers stable high water permeability with minimal clogging and higher permeate water quality.

The plate-and-frame configuration employs flat sheet membranes and is inherently stronger against fouling than the hollow fibre membrane configuration. Therefore, it results in fewer chemical cleaning requirements. Reduced module fouling from human hair and other obstructive substances requiring only coarse screening as a pre-treatment process.